Blog

2025 Top 10 Electrical Cable Tray Innovations You Can't Miss

As we step into 2025, the electrical cable tray industry is poised for a transformative evolution that promises efficiency, sustainability, and enhanced safety features. The global market for electrical cable trays is projected to reach $6.8 billion by 2025, growing at a CAGR of 6.1% from 2020, according to the latest industry report by MarketsandMarkets. This upward trend signals a significant shift towards innovative solutions that not only meet but exceed the growing demands for modern electrical installations.

Industry expert John Smith, a leading figure at the International Electrotechnical Commission, emphasizes, "The advancements we are witnessing in electrical cable tray systems are redefining the standards for installation and maintenance in a way that enhances productivity and reduces downtime." His insights highlight the critical role that innovations such as modular designs, sustainable materials, and smart monitoring technology will play in shaping the future landscape of electrical infrastructure.

As we explore the top ten electrical cable tray innovations you can't miss in 2025, it is essential to consider how these developments will contribute to efficiency and sustainability within various sectors. From data centers to manufacturing plants, the integration of advanced cable management solutions will not only optimize performance but also address the increasing environmental concerns driving industry standards.

Revolutionary Materials Redefining Electrical Cable Tray Durability

The electrical cable tray industry is witnessing a significant transformation with the introduction of revolutionary materials that are reshaping durability standards. Innovative composites and engineered plastics are at the forefront, offering superior resistance to harsh environments, chemicals, and temperatures. These advancements not only enhance the lifespan of cable trays but also reduce maintenance costs for businesses, making them a smart investment for the future.

**Tips:** When selecting cable trays, consider the material's environmental resistance. Look for trays made from materials like fiberglass or high-density polyethylene, which offer better protection against corrosion and UV rays. Additionally, ensure that the trays meet relevant industry standards for load-bearing and fire safety, ensuring long-term performance and compliance.

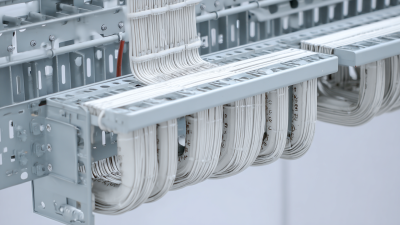

Another notable innovation involves the use of lightweight, modular designs that facilitate easier handling and installation. This approach not only accelerates project timelines but also allows for flexibility in adapting to various layouts. As the industry continues to evolve, staying updated on these innovations can lead to more efficient installations and enhanced infrastructure reliability.

**Tips:** Always consult with manufacturers about the latest material options and how they align with your specific project requirements. Incorporating these innovations into your planning process can lead to more sustainable and resilient electrical systems.

2025 Top 10 Electrical Cable Tray Innovations You Can't Miss - Revolutionary Materials Redefining Electrical Cable Tray Durability

| Innovation | Material Type | Durability Rating | Weight Capacity (lbs) | Resistance Features |

|---|---|---|---|---|

| Ultra-Light Composite Tray | Composite Material | High | 500 | Corrosion and UV Resistance |

| Fire-Resistant Tray | Steel Alloy | Very High | 700 | Fire and Heat Resistance |

| Flexible Cable Tray System | Polyethylene | Medium | 300 | Impact and Chemical Resistance |

| Modular Cable Tray Solutions | Aluminum | High | 600 | Corrosion and Lightweight |

| Anti-Bacterial Tray | Copper | Very High | 500 | Bacterial Resistance |

| Eco-Friendly Tray | Recycled Materials | Medium | 400 | Eco-Friendly and Non-Toxic |

| High-Temp Resistant Tray | Fiberglass | Very High | 550 | Heat and Flame Resistance |

| Wire Management Tray | Plastic Composite | Medium | 350 | Flexible and Lightweight |

| Weather-Resistant Tray | Zinc-Coated Steel | High | 650 | Rust and Moisture Resistance |

| Vibration Dampening Tray | Reinforced Plastic | Medium | 375 | Vibration and Shock Absorption |

Smart Cable Tray Systems with Integrated Monitoring Technology

The emergence of smart cable tray systems equipped with integrated monitoring technology marks a significant shift in how electrical infrastructure is managed and maintained. These innovative solutions provide real-time data analytics, allowing facility managers to monitor cable conditions, temperature variations, and potential overloads. By leveraging IoT (Internet of Things) capabilities, these systems offer proactive insights that can prevent downtime and ensure optimal performance.

Moreover, the integration of smart technology within cable trays enhances safety and efficiency. Advanced sensors can alert users to potential issues before they escalate, reducing the risk of electrical failures and fires. This predictive maintenance approach not only saves costs associated with reactive repairs but also extends the lifespan of electrical components. As industries continue to prioritize sustainability and operational efficiency, the adoption of these cutting-edge cable tray systems will be pivotal in shaping the future of electrical management.

Eco-Friendly Solutions: Sustainable Innovations in Cable Tray Design

The growing emphasis on sustainability in the construction and electrical industries has led to significant innovations in cable tray design. Eco-friendly materials are becoming increasingly prevalent, replacing traditional metals and plastics with recyclable options such as high-density polyethylene (HDPE) and other biodegradable composites. These materials not only reduce environmental impact but also enhance the durability and longevity of cable trays, proving that sustainability and performance can go hand in hand.

In addition to material innovations, manufacturers are also focusing on sustainable production processes. Energy-efficient manufacturing techniques, such as using renewable energy sources and minimizing waste through lean production practices, are gaining traction. Furthermore, designs are being optimized for ease of disassembly and recycling at the end of their lifecycle, ensuring that cable trays contribute to a circular economy.

As these eco-friendly solutions emerge, they are setting new industry standards, demonstrating that innovation in cable tray design can drive both performance and environmental responsibility.

Space-Saving Cable Tray Configurations for Optimized Industrial Layouts

As industries evolve, the demand for effective space management becomes increasingly critical. Space-saving cable tray configurations are at the forefront of this necessity, optimizing layouts while ensuring safety and efficiency. Innovative designs such as vertical cable trays and dual-level installations allow companies to maximize vertical space, which is particularly beneficial in facilities with limited floor areas. These configurations not only reduce clutter but also streamline maintenance, making it easier to access cables for upgrades or repairs.

Tips: When evaluating space-saving options, consider using modular cable trays that can be easily adjusted to fit specific layouts. Additionally, integrating cable management systems that include labeling and organization features will further enhance accessibility and minimize confusion during inspections or maintenance.

Moreover, the implementation of lightweight materials in cable trays contributes significantly to both ergonomics and structural integrity. By choosing trays made from advanced composites or aluminum, businesses can mitigate installation challenges and weight-related concerns. This not only translates to easier handling but also helps in creating layouts that are adaptable to future needs without significant disruptions.

Tips: Always involve your installation team when selecting materials; their insights can ensure that the chosen trays both meet functional requirements and align with the unique space constraints of your facility.

Enhanced Safety Features: Addressing Fire and Electrical Hazards in Cable Trays

The electrical industry is continually evolving, with safety being a paramount concern. Recent innovations in cable tray designs have focused on enhancing safety features to mitigate fire and electrical hazards. According to a report by Market Research Future, the global cable tray market is projected to reach USD 5.6 billion by 2025, highlighting the growing emphasis on safer electrical installations. This surge is partly driven by the need for compliance with stringent safety regulations and standards.

One of the key advancements is the introduction of fire-resistant materials in cable trays. These materials not only withstand higher temperatures but also slow down the spread of flames, significantly reducing potential fire hazards in industrial settings. A study published in the IEEE Transactions on Industry Applications indicates that cable tray systems equipped with advanced fire-resistant insulation can reduce the risk of electrical fires by up to 40%. Such innovations are critical as organizations aim to protect both their assets and personnel from electrical dangers more effectively.

2025 Top 10 Electrical Cable Tray Innovations

Related Posts

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

Maximizing Safety and Efficiency: The Growing Demand for Basket Cable Trays in Modern Infrastructure

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

Exploring Innovative Alternatives to Traditional Cable Tray Wire Systems

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now