Blog

What is a B Line Cable Tray and How to Choose the Right One

In today's fast-paced industrial environment, the efficient management of electrical wiring is crucial for ensuring safety and functionality. One essential component in this realm is the B Line cable tray, which provides a structured solution for organizing and supporting electrical cables. Whether in commercial buildings, manufacturing plants, or data centers, B Line cable trays help streamline the installation process while minimizing the risk of damage to the cables, thus enhancing overall system reliability.

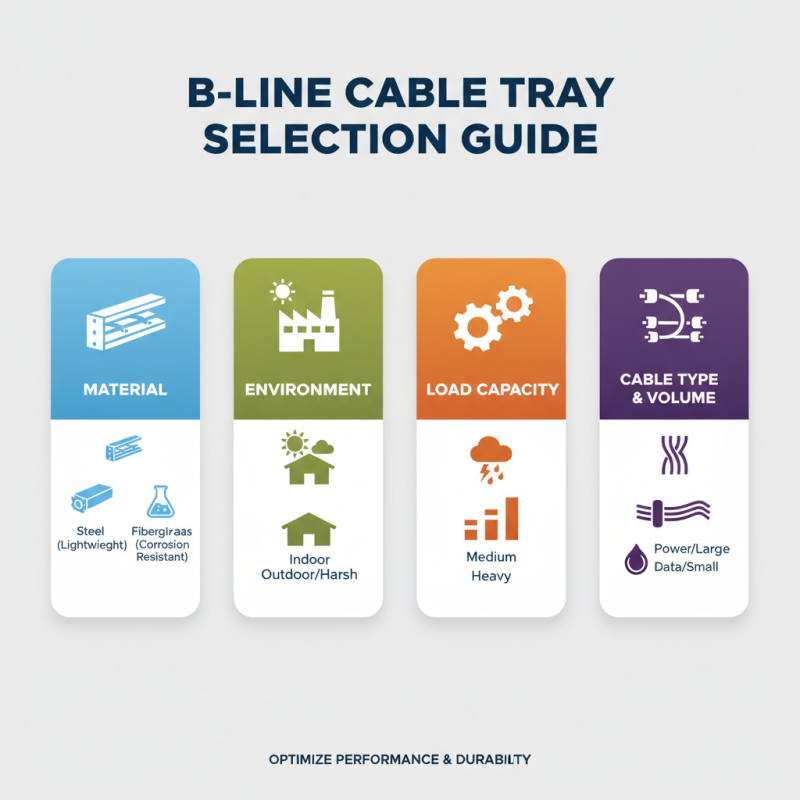

Choosing the right B Line cable tray involves understanding its various types, materials, and applications. Different environments may require specific features, such as ruggedness in heavy-duty settings or versatility in space-constrained areas. By considering factors like load capacity, installation requirements, and environmental conditions, businesses can ensure that they select the most appropriate cable tray to meet their needs. This guide aims to shed light on the significance of B Line cable trays and provide a clear roadmap for making informed choices that promote efficiency and safety in cable management systems.

What is a B Line Cable Tray and Its Main Functions

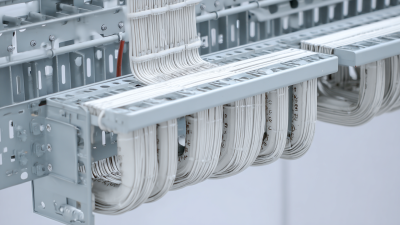

A B Line Cable Tray is a vital component in industrial and commercial electrical installations. Its primary function is to support and organize electrical cables, preventing them from tangling and ensuring easy access for maintenance. The design of a B Line Cable Tray allows for efficient heat dissipation, which is crucial in preventing overheating of cables and ensuring operational safety. Typically made from durable materials like steel or aluminum, these trays are often installed in various configurations—such as ladder, perforated, or solid bottom—to accommodate different types of wiring systems.

When selecting the right B Line Cable Tray, one must consider several factors. Firstly, evaluate the cable load requirements, taking into account the types and sizes of cables that will be used. Additionally, the environmental conditions in which the tray will be installed play a significant role; for instance, outdoor installations may require corrosion-resistant materials. Another critical aspect is the compliance with local regulations and standards, which ensure safe and reliable setups. Thus, understanding the specific needs of your project will guide you in choosing the most appropriate B Line Cable Tray, enhancing both functionality and safety in your electrical system.

Key Features of B Line Cable Trays to Consider

When selecting a B Line cable tray, it is crucial to consider several key features that will influence its performance and suitability for your specific application. First, the material of the cable tray is a fundamental factor, as it determines durability and resistance to environmental factors. Options like steel, aluminum, and fiberglass each have unique strengths; for instance, aluminum may offer lightweight benefits, while fiberglass can provide outstanding corrosion resistance. It is essential to choose a material that aligns with the installation environment, whether it be indoors or exposed to harsh conditions.

Another important consideration is the load capacity of the cable tray. B Line cable trays come in various configurations and sizes to accommodate different weights and amounts of cabling. It is necessary to assess the total weight of the cables to ensure that the chosen tray can handle the load without risk of failure. Additionally, the design of the cable tray, including its width and depth, should be suitable for the type and number of cables being used. A proper fit will not only ensure safety and compliance with regulations but also facilitate ease of installation and maintenance in the long run.

Factors to Assess When Choosing a B Line Cable Tray

When selecting a B Line cable tray, several key factors must be assessed to ensure optimal performance and compatibility with your installation requirements. First, consider the material of the tray; options such as steel, aluminum, or fiberglass each have unique properties that affect durability, weight, and corrosion resistance. Steel is often chosen for its strength and cost-effectiveness, while aluminum is lightweight and resistant to corrosion, making it suitable for environments where moisture is a concern. Fiberglass is ideal for applications requiring higher resistance to chemicals or extreme temperatures.

Another critical factor is the size and load capacity of the cable tray. Proper sizing ensures that all cables will fit comfortably without risk of overcrowding, which can lead to damage or overheating. Assess the number and types of cables you plan to install—considering both current and future needs—will help you choose a tray that accommodates your requirements. Additionally, pay attention to the tray design, including features such as adjustable supports and cable management accessories that can enhance organization and ease of maintenance. Evaluating these elements will guide you in selecting the right B Line cable tray for your project.

Factors to Assess When Choosing a B Line Cable Tray

Different Applications and Industries for B Line Cable Trays

B Line cable trays are versatile support systems commonly used in various applications, ranging from industrial facilities to commercial buildings. Their design facilitates the efficient management of electrical wiring and cabling, providing a structured pathway for optimal accessibility and protection. Industries such as telecommunications, oil and gas, and manufacturing significantly benefit from B Line cable trays, where reliable cable management is critical to operational efficiency. According to a recent market analysis, the global cable tray market is projected to grow at a CAGR of 5.3% from 2021 to 2028, indicating an increasing demand across multiple sectors.

In industrial environments, B Line cable trays are essential for accommodating large volumes of electrical cables and equipment. They enhance safety by minimizing the risks of cable damage and electrocution, while also supporting compliance with local safety regulations. In the telecommunications sector, these trays are utilized to organize fiber optic and copper cables, crucial for maintaining network reliability. Furthermore, with the rise of smart buildings and renewable energy projects, the need for efficient cable management solutions in sectors such as construction and energy is increasingly recognized. The versatility of B Line cable trays enables their adaptation for varying weight loads and cable types, ensuring they meet the specific needs of diverse industries.

What is a B Line Cable Tray and How to Choose the Right One - Different Applications and Industries for B Line Cable Trays

| Application | Industry | Material | Load Capacity (lbs) | Tray Width (inches) |

|---|---|---|---|---|

| Electrical Wiring | Construction | Steel | 600 | 6 |

| Data Cabling | Telecommunications | Aluminum | 400 | 12 |

| HVAC Systems | Manufacturing | Galvanized Steel | 800 | 8 |

| Industrial Wiring | Industrial | Stainless Steel | 1000 | 10 |

| Cable Management | Energy | PVC Coated Steel | 500 | 18 |

Installation Best Practices for B Line Cable Trays

When installing B Line cable trays, adherence to best practices is essential for ensuring a safe, efficient, and durable installation. According to the National Electrical Contractors Association (NECA), nearly 30% of electrical installation delays can be attributed to improper wiring methods and inadequate planning. To avoid such setbacks, it's crucial to conduct a thorough site assessment and develop a comprehensive installation plan. This involves understanding the load requirements, environmental factors, and layout, ensuring that the chosen cable tray system is adequate to handle anticipated cable volumes and weights.

Proper installation techniques also play a significant role in the longevity and functionality of B Line cable trays. It is recommended to maintain a minimum of 12 inches of clearance above ground level to facilitate maintenance access and avoid water accumulation. Additionally, following the guidelines set forth by the American National Standards Institute (ANSI) can help prevent potential safety hazards. The report by the National Fire Protection Association (NFPA) indicates that improperly installed cable trays can lead to increased fire risks, highlighting the importance of secure mounting, proper grounding, and spacing to prevent overheating. By considering these aspects during installation, professionals can ensure a reliable and compliant cable tray system that meets industry standards.

Related Posts

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

Top 10 Best Electrical Cable Trays for Efficient Cable Management in 2023

-

2025 Top 10 Electrical Cable Tray Innovations You Can't Miss

-

Understanding the Importance of Cable Tray Wire in Modern Electrical Installations

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now