Blog

Understanding the Benefits of FRP Cable Tray in Modern Electrical Systems

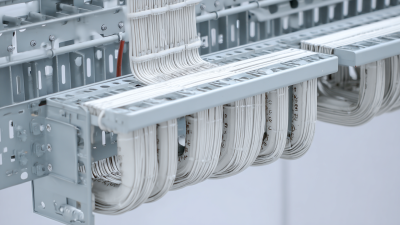

The growing complexity and demand for modern electrical systems have necessitated the use of innovative materials and components that enhance efficiency and safety. One such component gaining significant traction is the FRP (Fiber-Reinforced Polymer) cable tray, which has emerged as a vital solution in various industrial sectors. According to a report by MarketsandMarkets, the global FRP market is projected to reach USD 163.71 billion by 2024, with cable trays being a key application area. The unique properties of FRP, including its corrosion resistance, lightweight nature, and high tensile strength, make it an ideal choice for environments facing harsh conditions, where traditional materials may fail. Additionally, using FRP cable trays not only ensures compliance with safety standards but also contributes to longer service life and reduced maintenance costs, making it a sustainable choice for modern electrical installations.

The Advantages of Using FRP Cable Tray in Electrical Installations

FRP (Fiberglass Reinforced Plastic) cable trays have emerged as a vital component in modern electrical installations, driven by their unique advantages over traditional materials. One significant benefit is their lightweight nature, which can drastically reduce installation labor costs. According to a report by the National Electrical Manufacturers Association (NEMA), the use of FRP in cable trays can lead to up to a 50% decrease in weight compared to metal alternatives, simplifying handling and transportation. This reduction not only speeds up the installation process but also minimizes the need for heavy lifting equipment, making it a cost-effective solution for complex electrical systems.

Additionally, FRP cable trays boast superior corrosion resistance, making them ideal for challenging environments such as chemical plants or coastal regions. A study conducted by the Composites Industry Association found that FRP systems can withstand harsh conditions for over 30 years without deterioration, whereas traditional metal trays may require frequent replacements. This longevity results in significant maintenance savings and reduces downtime in industrial operations.

The thermal and electrical insulating properties of FRP also enhance safety, reducing heat buildup and the risk of electrical hazards, which is crucial in high-load applications. Overall, the adoption of FRP cable trays stands as a testament to the industry's shift towards more durable, efficient, and cost-effective installation solutions.

Why FRP Cable Tray is Ideal for Harsh Environments

Fiber Reinforced Polymer (FRP) cable trays are becoming increasingly essential in modern electrical systems, particularly in harsh environments. These composite materials offer exceptional resistance to corrosion, temperature fluctuations, and mechanical stresses, making them ideal for industries such as chemical processing, marine applications, and oil and gas. The global FRP cable tray market is projected to expand significantly, reaching approximately $696.78 million by 2032 with a compound annual growth rate (CAGR) of 8.36% from 2019, reflecting the rising demand for durable and reliable cable management solutions.

In environments that pose significant challenges, FRP cable trays outperform traditional materials like steel and aluminum. Their lightweight nature simplifies installation and reduces the structural load, while their high resistance to harsh chemicals ensures longevity. Moreover, as infrastructure projects increasingly prioritize sustainability and maintenance efficiency, the role of FRP cable tray systems is likely to expand. The cable tray market as a whole is expected to reach $12.89 billion by 2032, indicating a robust growth trajectory fueled by innovations in materials and design tailored for high-performance in demanding conditions.

Cost-Effectiveness of FRP Cable Tray Over Traditional Materials

The use of Fiberglass Reinforced Plastic (FRP) cable trays has gained substantial attention in modern electrical systems, particularly due to their cost-effectiveness compared to traditional materials like steel and aluminum. One of the significant advantages of FRP cable trays is their lightweight nature, which reduces installation costs and labor time. Moreover, FRP’s resistance to corrosion and various chemicals ensures longevity and less frequent maintenance, translating to lower lifecycle costs.

Tips: When considering FRP cable trays, it’s essential to evaluate your specific electrical application to ensure compatibility with your existing infrastructure. Additionally, assessing the environmental impact of materials can further enhance the sustainability of your project.

Furthermore, FRP cable trays often exhibit better thermal insulation properties compared to their metal counterparts. This characteristic can help in protecting the cables from extreme temperatures, thus improving operational efficiency and safety. Opting for FRP can not only provide financial benefits but also contribute to a more sustainable and eco-friendly electrical infrastructure.

Tips: Make sure to consult with a specialist to choose the right type of FRP that fits your project requirements, ensuring optimal performance and cost savings over time.

Why FRP Cable Tray Ensures Enhanced Safety and Reliability

FRP (Fiber Reinforced Plastic) cable trays have become increasingly popular in modern electrical systems due to their enhanced safety and reliability. Unlike traditional materials such as steel and PVC, FRP offers exceptional resistance to corrosion, making it ideal for demanding environments. The global market for FRP cable trays is expected to see substantial growth, with a valuation projected to reach USD 696.78 million by 2032, up from USD 253.48 million in 2019. This growth underscores the importance of FRP materials in ensuring the longevity and performance of electrical systems.

In terms of safety, FRP cable trays are non-conductive and do not support combustion, significantly reducing the risk of electrical hazards. Moreover, their lightweight nature makes installation easier and reduces structural load, leading to safer installations. As reported, the U.S. cable tray market alone was valued at USD 818.89 million in 2022, showcasing the rising demand for safer and more reliable solutions in the electrical industry. The advantages of FRP continue to drive innovation, making it a preferred choice for many modern applications.

The Environmental Benefits of Choosing FRP Cable Tray for Electrical Systems

The environmental benefits of choosing FRP (Fiber Reinforced Polymer) cable trays in modern electrical systems are increasingly recognized within the industry. According to a report by ResearchAndMarkets, the global FRP market is projected to grow, driven by its eco-friendly properties and sustainability. Unlike traditional metal cable trays, FRP materials are resistant to corrosion, which decreases the need for replacement and maintenance, thus reducing waste. This durability contributes to longer life cycles for electrical infrastructure and minimizes the environmental impact throughout their lifespan.

Additionally, FRP cable trays are often manufactured using less energy-intensive processes compared to their metallic counterparts. The U.S. Department of Energy estimates that using FRP can lead to a reduction of up to 30% in energy consumption during manufacturing. Moreover, the lightweight nature of FRP reduces transportation emissions, making it a greener option for construction projects. As companies strive for greener solutions to meet regulatory requirements and corporate sustainability goals, incorporating FRP cable trays can significantly enhance the environmental profile of electrical systems, demonstrating a commitment to both innovation and ecological responsibility.

Related Posts

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

How to Select the Right Basket Cable Tray for Your Wiring Needs

-

Ultimate Guide to Choosing the Right Mesh Cable Tray for Your Project

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now