Blog

Top 10 Benefits of Using Cable Tray for Your Electrical Wiring Needs

In recent years, the demand for efficient and organized electrical wiring solutions has significantly increased across various industries. One of the most effective methods to achieve this is through the use of cable trays. According to a report by the Electrical Association, the global cable tray market is projected to reach $10 billion by 2025, driven by the need for streamlined electrical installations and robust infrastructure. The adoption of cable trays not only enhances safety and compliance but also contributes to overall project efficiency, making them an essential component in modern electrical design.

As noted by industry expert Dr. James Halpert, a leading authority in electrical infrastructure design, "Cable trays are not just an aesthetic choice; they are a critical element in enhancing the safety and reliability of electrical systems." With their ability to support a wide range of cable types while minimizing damage, cable trays serve a dual purpose of organization and protection. This strategic advantage positions cable trays as a top solution for managing electrical wiring needs in commercial, industrial, and residential settings.

In light of these advantages, exploring the top benefits of cable trays becomes crucial for industry professionals looking to optimize their electrical systems. By understanding how cable trays contribute to safety, efficiency, and ease of maintenance, stakeholders can make informed decisions that align with best practices in electrical installation and management.

Benefits of Cable Trays: Enhancing Electrical Safety and Efficiency

Cable trays are essential components in modern electrical installations, providing a structured path for electrical wiring while enhancing safety and efficiency. One of the primary benefits of using cable trays is the minimization of electromagnetic interference (EMI). By organizing cables adequately, cable trays help reduce noise and electromagnetic disturbances, which can significantly improve the performance of electrical systems. This organized layout also simplifies troubleshooting, allowing technicians to easily identify and access specific wires without wading through a tangled mass of cables.

In addition to improving safety by reducing the risk of cable damage, cable trays help maintain compliance with electrical codes and regulations. They facilitate proper air circulation around cables, which in turn helps prevent overheating and prolongs the lifespan of the wires. Furthermore, cable trays are designed to support a variety of cable types, allowing for flexibility in electrical design and easy upgrades or modifications as needed. This adaptability makes cable trays a valuable investment for any electrical project, ensuring that safety and efficiency remain top priorities throughout the lifespan of the installation.

Top 10 Benefits of Using Cable Tray for Your Electrical Wiring Needs

Improved Organization and Accessibility of Electrical Wiring Systems

The organization and accessibility of electrical wiring systems are paramount in today's fast-paced construction and maintenance environments. Utilizing cable trays can significantly enhance these aspects by providing a structured framework that supports and organizes electrical cables. A report from the National Electrical Manufacturers Association (NEMA) indicates that a well-organized cable management system can reduce maintenance time by up to 30%. This reduction stems from the ease of locating and accessing wiring components, which minimizes downtime and enables quicker responses during repairs or upgrades.

Additionally, cable trays promote safety and compliance with electrical standards, as organized wiring systems are less prone to accidental damage or malfunctions. According to a study by the International Electrotechnical Commission (IEC), systematically installed cable trays can lead to a 20% decrease in electrical hazards associated with improper wiring. With designated pathways for cables, electricians and maintenance personnel can maneuver with confidence, knowing that the risk of tangles and overloading is mitigated. This contributes to a more efficient work environment, where accessibility supports timely interventions and enhances overall project productivity.

Top 10 Benefits of Using Cable Tray for Your Electrical Wiring Needs

| Benefit | Description | Accessibility Rating (1-5) |

|---|---|---|

| Improved Organization | Cable trays help manage and organize your wiring system, reducing clutter. | 5 |

| Enhanced Durability | Engineered to withstand environmental stresses, prolonging cable life. | 4 |

| Easier Maintenance | Provides easy access to the wiring for troubleshooting and repairs. | 5 |

| Cost Efficiency | Reduces installation time and costs with simplified wiring management. | 4 |

| Flexibility | Allows for easy reconfiguration of wiring layout without excessive effort. | 5 |

| Improved Safety | Reduces the risk of cable damage and electrical hazards. | 5 |

| Thermal Management | Allows for better air circulation around cables, reducing heat buildup. | 4 |

| Aesthetic Appeal | Provides a clean and professional look to electrical installations. | 3 |

| Compatibility | Compatible with various types of cable systems and installations. | 5 |

| Customizable Design | Can be tailored to meet specific project requirements and layouts. | 4 |

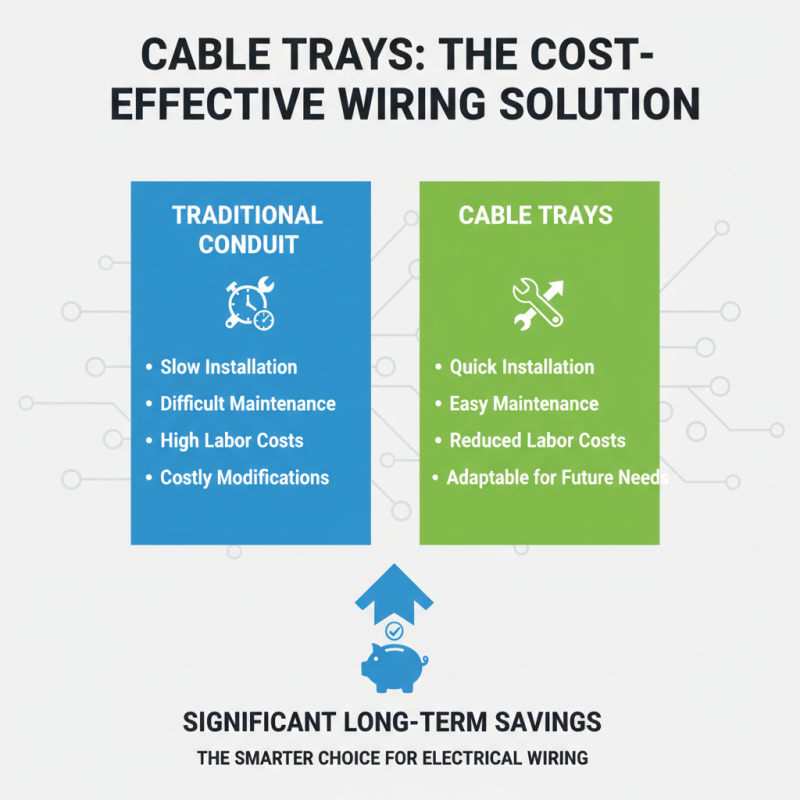

Cost-Effectiveness: Long-Term Savings through Cable Tray Solutions

Cost-effectiveness is a crucial aspect when considering solutions for electrical wiring needs, and cable trays offer significant long-term savings. Unlike traditional conduit systems, cable trays facilitate quicker installation and easier maintenance, which can greatly reduce labor costs. Since trays allow for the easy relocation or addition of wiring as requirements change, companies save money on future modifications. This adaptability eliminates the need for costly reworks, making cable trays a financially savvy choice.

Moreover, cable trays are typically made from durable materials that resist corrosion and wear, which can extend their lifespan and reduce replacement costs. Their open design promotes better airflow and minimizes overheating, enhancing the longevity of the cables they hold. This further translates to fewer outages or repairs, leading to savings on operational downtime. Overall, investing in cable tray systems can lead to a more efficient allocation of resources, not just during initial setup but throughout the entire lifespan of the electrical infrastructure.

Reduction of Installation Time and Labor Costs in Wiring Projects

Using cable trays in electrical wiring projects can significantly reduce installation time and labor costs. When compared to traditional conduit systems, cable trays provide a more streamlined approach to organizing and supporting electrical wires. Since cable trays allow for both horizontal and vertical arrangements, the routing of cables becomes simpler and more efficient. Installers can quickly lay down the trays and secure wiring without the need for extensive preparation. This not only accelerates the installation process but also minimizes the potential for errors, which can lead to costly rework.

Moreover, the ease of access that cable trays provide can greatly benefit future modifications or maintenance. In traditional systems, electricians often find themselves spending additional time tracing or accessing wires hidden behind walls or within conduits. With cable trays, wires are neatly organized and remain visible, making troubleshooting and upgrades easier. Fewer labor hours spent on both installation and maintenance contribute to reduced overall costs, making cable trays an attractive option for project managers eager to stay within budget while enhancing efficiency.

Enhanced Airflow and Heat Dissipation for Electrical Components

Cable trays have emerged as a crucial component in modern electrical installations, especially concerning enhanced airflow and heat dissipation for electrical components. Effective thermal management is essential in maintaining peak performance and longevity of electrical systems. According to the National Fire Protection Association (NFPA), improper heat management can lead to system failures and increased risks of fire hazards. Cable trays facilitate better airflow around cables, preventing heat buildup and allowing temperature regulation which is pivotal for sensitive electrical components.

In a study conducted by the International Electrical Testing Association (IETA), it was found that systems utilizing cable trays exhibited a 30% improvement in heat dissipation compared to traditional conduit systems. This is primarily because the open design of cable trays promotes unobstructed air circulation, enabling cooler air to reach electrical components and reducing the likelihood of overheating. Furthermore, effective heat management not only prolongs the life of electrical equipment but also enhances overall system efficiency, leading to lower energy costs. Proper installation and configuration of cable trays can significantly contribute to the operational reliability of electrical systems, thus emphasizing their importance in industrial and commercial settings.

Related Posts

-

2025 Top 10 Electrical Cable Tray Innovations You Can't Miss

-

Top 10 Best Electrical Cable Trays for Efficient Cable Management in 2023

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

Exploring Innovative Alternatives to Traditional Cable Tray Wire Systems

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now