Blog

Best Metal Cable Tray Designs for Efficient Cable Management?

In today's fast-paced industrial environment, efficient cable management is essential. Metal cable trays play a crucial role in maintaining organization. They facilitate improved airflow, reduce heat buildup, and prevent cable damage. According to a report by the National Electrical Contractors Association, proper cable management can boost system longevity by up to 30%.

Selecting the right metal cable tray design can significantly enhance efficiency. Different designs cater to various applications, such as enclosed, ladder, and trough trays. Each design serves distinct purposes while adhering to safety regulations. Yet, many companies fail to evaluate their specific needs, leading to misplaced investments.

Realigning your focus on tailored solutions is necessary. An ideal metal cable tray system should not just be functional but also adaptable. A report from the International Electrotechnical Commission emphasizes the importance of customization in minimizing disruptions. As industries continue to evolve, staying ahead in cable management requires ongoing reflection and adjustment.

Overview of Metal Cable Tray Types for Effective Management

When considering metal cable trays, it’s essential to understand the various types available. Steel trays are popular due to their strength. They can handle heavy cables and are durable. Aluminum trays are lighter and resistant to corrosion. This makes them suitable for environments with moisture. Each type serves specific needs in cable management.

Cable trays come in different styles. Solid-bottom trays provide extra protection and support for heavy wires. Ventilated trays allow air circulation, reducing heat. Ladder trays offer flexibility, accommodating many cables without excess weight. However, one must reflect on the right choice. Not all installations require heavy-duty trays. Sometimes, a simpler design suffices. Careful consideration is vital to avoid over-specifying the tray type, leading to unnecessary costs.

Choosing poorly can result in ineffective management and clutter. It’s common to overlook the importance of proper spacing. This can lead to heat issues or even safety hazards. Assessing the specific environment and requirements is crucial. Each type has its benefits, but the wrong choice can complicate cable management instead of simplifying it.

Best Metal Cable Tray Designs for Efficient Cable Management

| Tray Type | Material | Load Capacity (lbs) | Applications | Advantages |

|---|---|---|---|---|

| Ladder Tray | Steel | 400 | Power Generation, Industrial | Easy installation, good ventilation |

| Solid Bottom Tray | Aluminum | 300 | Data Centers, Telecommunication | Protection from dust, corrosion resistant |

| Wire Mesh Tray | Galvanized Steel | 250 | Commercial Buildings | Lightweight, flexible installation |

| Perforated Tray | Stainless Steel | 350 | Pharmaceuticals, Hospitals | Highly durable, easy to clean |

| Cable Tray with Covers | Carbon Steel | 500 | Manufacturing Plants | Enhanced protection for cables, aesthetic appeal |

Benefits of Using Metal Cable Trays in Cable Management Systems

Metal cable trays are a vital component in modern cable management systems. They provide a robust solution for organizing and supporting electrical cables, ensuring safety and efficiency. The strength of metal trays means they can bear heavy cable loads without sagging or breaking. This durability leads to fewer maintenance issues over time.

Using metal cable trays simplifies installation. They can be easily mounted to walls or ceilings. This not only saves space but also enhances the overall aesthetic of facilities. Additionally, metal trays resist fire and are less prone to wear compared to plastic alternatives. However, one might consider the potential for corrosion in certain environments. Regular inspections and maintenance can mitigate this concern.

Employing metal trays can lead to more effective airflow around cables, reducing overheating. This is crucial in preventing downtime caused by equipment failure. While the initial cost may be higher, the long-term benefits often outweigh this. Ensuring that cable management is both efficient and safe creates a more reliable electrical infrastructure.

Key Considerations for Selecting Metal Cable Tray Designs

When selecting metal cable tray designs, several key considerations come into play. One major factor is the material quality. According to industry reports, trays made from steel can support heavier loads than aluminum counterparts. This directly affects durability and performance in demanding environments. Aside from material, the dimensions of the cable trays matter. Width and height determine how many cables a tray can accommodate. Inadequate sizing can lead to overcrowding and potential damage to cables.

Installation and maintenance are also vital factors. Simple installation procedures save time and costs. However, some metal trays may present challenges during installation, requiring additional labor or tools. Data reveals that poor installation can reduce system efficiency by up to 20%. Therefore, a balance between ease of setup and structural integrity is essential. Ease of access for future maintenance should not be overlooked. Trays that are difficult to reach can lead to delays and frustrations when upgrades or repairs are necessary.

Environmental factors should influence design choices too. If the tray will be exposed to moisture or corrosive elements, selecting a protective finish is crucial. However, many options come with caveats. Some coatings may wear off over time, necessitating replacements sooner than intended. Balancing cost-effectiveness with longevity can be a challenge, especially in fast-paced industries. A thoughtful approach to these considerations leads to better cable management solutions.

Best Metal Cable Tray Designs for Efficient Cable Management

This chart represents different types of metal cable tray designs and their efficiency ratings in cable management. The efficiency ratings are based on factors such as installation ease, durability, and load capacity.

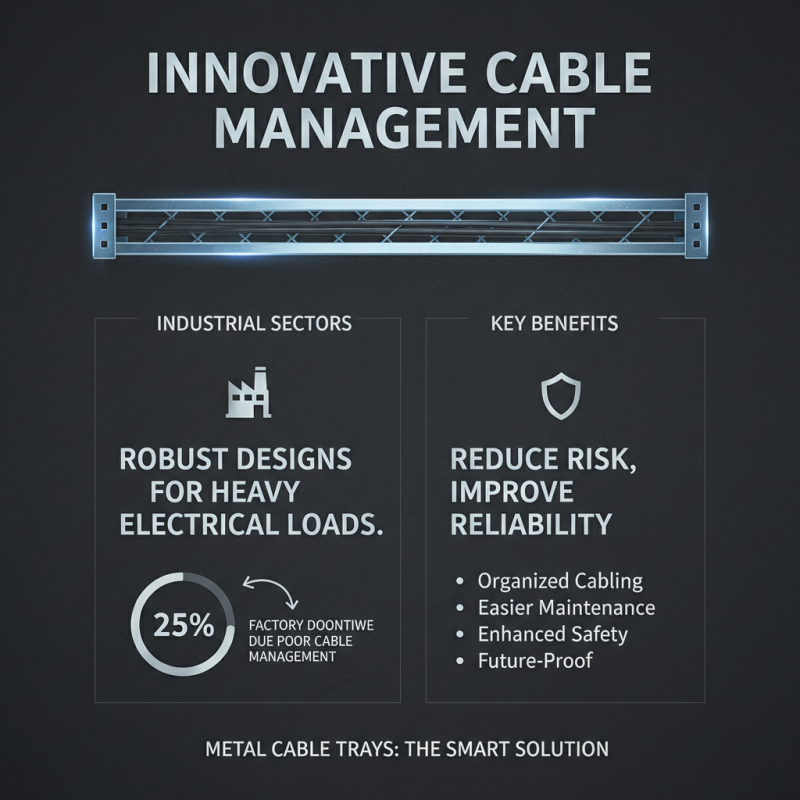

Creative Design Ideas for Metal Cable Trays in Various Industries

Metal cable trays offer innovative solutions for cable management across various sectors. In industrial settings, robust designs accommodate heavy electrical loads. According to a recent industry report, approximately 25% of downtime in factories is due to poor cable management. A well-designed tray system can significantly reduce this risk.

In the data center industry, effective cable organization is crucial. An optimized layout enhances airflow, preventing overheating. Research indicates that proper cable management can improve energy efficiency by up to 30%. Yet, many facilities still struggle with cluttered setups. Using modular designs allows for easy modifications as needs change.

Creative designs in metal cable trays are not just functional. They can also complement the aesthetics of modern workplaces. Using colored coatings can help distinguish between different types of cables. However, reflection on these designs shows that many overlook maintenance needs. Regular checks are necessary to ensure longevity and performance.

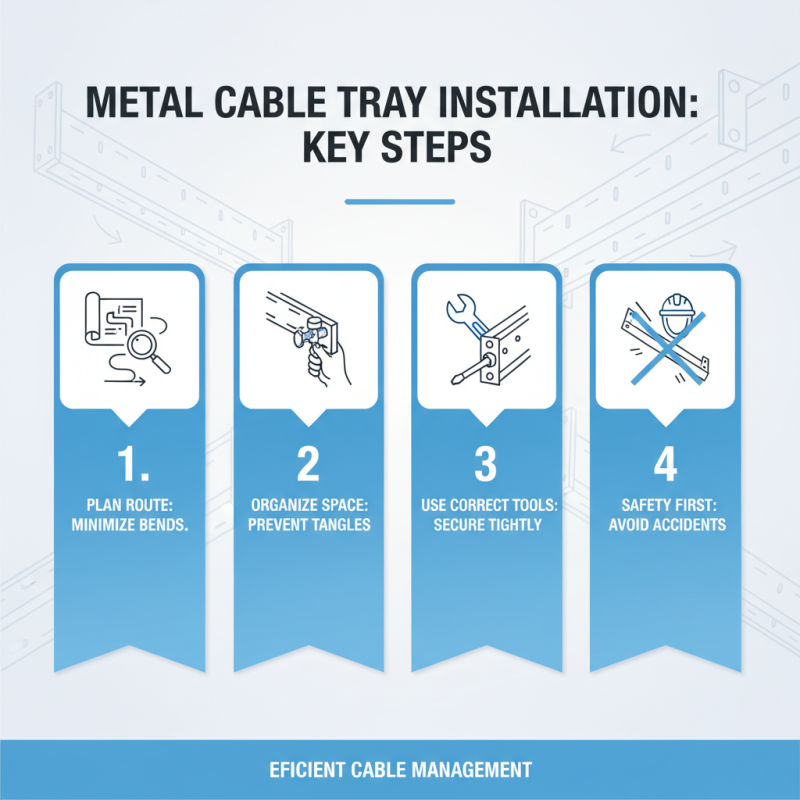

Best Practices for Installing and Maintaining Metal Cable Trays

When installing metal cable trays, proper planning is key. Make sure to choose a suitable location that minimizes bends and obstacles. This helps maintain effective cable flow. Keep your workspace clean and organized. Nothing is more frustrating than tangled wires. Use appropriate tools to secure the trays tightly. Loose fittings can lead to accidents or damage.

Regular maintenance is essential for longevity. Inspect the trays frequently for wear and tear. Look for rust or corrosion, especially in humid environments. Clean the trays regularly to prevent dust build-up. Dust can create friction and heat, which may damage cables. Remember that a small oversight can lead to bigger problems later on.

During installation, safety should always come first. Wear protective gear while working with metal materials. A small slip can result in injury. Additionally, involve team members in the process to share responsibilities. Collaboration can lead to better outcomes. These practices not only enhance the effectiveness of cable management but also ensure the safety of everyone involved.

Related Posts

-

Ultimate Guide to Choosing the Right Mesh Cable Tray for Your Project

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

2025 Top 10 Electrical Cable Tray Innovations You Can't Miss

-

Top 10 Benefits of Using Cable Tray Wire for Efficient Wiring Solutions

-

Essential Tips for Installing Cable Tray Wire Efficiently and Safely

-

Best B Line Cable Tray Solutions for Efficient Cable Management

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now