Blog

Understanding the Challenges of Wire Cable Tray Systems: Insights and Solutions from Industry Experts

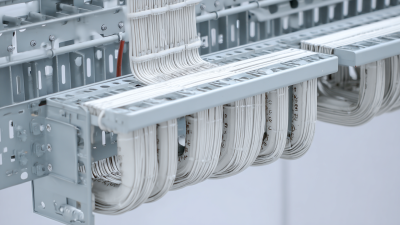

In today's rapidly evolving technological landscape, the importance of efficient cable management cannot be overstated. At the heart of this enterprise lies the wire cable tray systems, which serve as essential infrastructure for organizing and supporting wiring in commercial and industrial environments. While these systems offer numerous advantages, including enhanced safety, improved accessibility, and streamlined installation processes, they are not without their challenges. Industry experts have identified various obstacles that can impede the effectiveness of wire cable trays, ranging from design limitations to installation difficulties. In this blog, we will explore these challenges in depth, alongside valuable insights and practical solutions that can help optimize the use of wire cable trays in diverse applications. By understanding both the benefits and potential pitfalls, organizations can make informed decisions that promote efficiency and longevity in their electrical and communication systems.

Key Considerations for Selecting Wire Cable Tray Systems in Various Environments

When selecting wire cable tray systems for various environments, several key considerations must be taken into account to ensure optimal performance and safety. First and foremost, the environmental conditions play a significant role. For instance, installations in outdoor or industrial settings may require weather-resistant and durable materials that can withstand extreme temperatures, moisture, and pollutants. Conversely, indoor environments might prioritize aesthetics and accessibility, leading to a choice of more discreet designs that blend with the surrounding architecture.

Another critical aspect is the load capacity of the tray system. Understanding the weight and volume of cables, along with future expansion needs, is essential for selecting a system that can safely support the wiring infrastructure. Consultation with industry experts can provide insights into material options such as aluminum, steel, or fiberglass, each offering unique benefits. Additionally, compliance with local regulations and safety standards is paramount; selecting a cable tray system that adheres to these guidelines not only enhances safety but also streamlines installation processes. By carefully evaluating these factors, businesses can implement effective wire cable tray systems that guarantee functionality and longevity in their specific environments.

Understanding the Challenges of Wire Cable Tray Systems

| Consideration | Description | Environment Impact | Recommended Solutions |

|---|---|---|---|

| Material Selection | Choosing the right materials for durability and corrosion resistance. | Corrosive environments can severely damage insufficient materials. | Use stainless steel or coated materials for harsh environments. |

| Load Capacity | Understanding the weight limits for safe installations. | Overloading can lead to system failure and safety hazards. | Calculate load requirements and choose trays that exceed these values. |

| Accessibility | Ensuring that cable trays are easily accessible for maintenance. | Difficult access can result in higher maintenance costs. | Plan for accessibility in the design phase, including removable sections. |

| Thermal Expansion | Considering how temperature changes affect cable and tray integrity. | Improper allowance can lead to cable damage or failure. | Incorporate expansion joints in tray installations. |

| Regulatory Compliance | Following local and national electrical codes. | Non-compliance can result in fines and unsafe conditions. | Consult with regulations during the planning and installation phases. |

Common Challenges Faced in Wire Cable Tray Installation and Maintenance

Wire cable tray systems are essential for efficient cable management in various industries, but they come with a set of challenges that need to be addressed to ensure optimal performance. One of the most common issues faced during installation is the difficulty in aligning components properly, which can lead to structural weaknesses. A study published in *Mathematical Problems in Engineering* highlights the relationship between the strength and stiffness of cable trays, emphasizing that improper alignment not only jeopardizes stability but also escalates the risk of costly maintenance down the line.

Maintenance of wire cable tray systems is equally challenging. As the cable tray market is projected to grow from $4.15 billion in 2025 to $6.64 billion by 2035, addressing these maintenance challenges needs to be a priority for industries relying on these systems. Issues like dust accumulation and wear and tear can lead to increased downtime and operational inefficiencies. Consistent monitoring and adopting advanced materials for cable trays can play a pivotal role in mitigating these issues, ensuring that installations remain reliable and cost-effective while supporting the growing demands of modern infrastructures.

Understanding Common Challenges in Wire Cable Tray Systems

Insights from Experts: Best Practices for Wire Cable Tray Design

Designing effective wire cable tray systems is crucial for maintaining a safe and organized electrical installation. According to a recent industry report published by the National Electrical Manufacturers Association (NEMA), improper cable management can lead to increased maintenance costs and safety hazards. To mitigate these challenges, it's essential to follow best practices in wire cable tray design.

Tip 1: When planning your installation, consider the load capacity of the cable tray. NEMA standards recommend a load rating that accommodates future expansion, which can save costs in the long run.

Tip 2: Proper spacing between trays is vital. The Cable Tray Manufacturers Association (CTMA) suggests maintaining a minimum vertical distance of 12 inches between trays to allow for adequate airflow and prevent overheating of cables.

Incorporating these insights from industry experts can significantly enhance the reliability and efficiency of your wire cable tray systems. Developing a comprehensive design strategy that includes regular inspections and maintenance will ensure longevity and reduce failure risks.

Innovative Solutions for Enhancing Wire Cable Tray System Efficiency

The evolving landscape of wire cable tray systems is marked by both challenges and innovative solutions that can significantly enhance system efficiency. Industry experts emphasize the importance of optimizing materials and designs to better accommodate modern electrical and mechanical needs. As more businesses pivot towards sustainable practices, the choice of materials—ranging from steel to aluminum—plays a crucial role. By understanding the unique benefits and limitations of each type, organizations can ensure their cable tray systems are not only compliant but also effective in managing space and reducing maintenance costs.

Moreover, the introduction of advanced solutions like the EZ-Path® Cable Tray Retrofit Device exemplifies how technology can address specific issues in cable management. Designed to restore noncompliant and overfilled tray penetrations, this device accommodates a broad range of cable sizes while enhancing system safety and organization. Such innovations reflect the industry's commitment to adapting to evolving customer needs, ultimately leading to greater efficiency and reliability in wire cable management systems.

Future Trends in Wire Cable Tray Technology: What to Expect

The future of wire cable tray technology is shaped by several key trends that reflect the dynamic evolution of the industry. As the cable market is projected to grow significantly, from $140.63 billion in 2024 to $180 billion by 2035, the demand for innovative wire management solutions will only intensify. This growth drives manufacturers to rethink traditional wire cable tray systems, focusing on efficiency, adaptability, and sustainability. Industry experts highlight a push towards more modular designs that can accommodate changing technologies, particularly as industries pivot towards renewable energy and electric vehicle initiatives.

Moreover, advancements in materials, including the increased use of plastics in wire cable management, are becoming essential. The wire cable plastic market is experiencing a notable rise due to escalating electricity needs and infrastructure developments. This transition not only addresses functional requirements but also enhances environmental sustainability. As electric vehicles proliferate and renewable energy systems expand, the wire cable management landscape will likely adapt to incorporate smart technologies and automation, ultimately paving the way for more resilient and efficient infrastructures in the coming years.

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now