Blog

How to Choose the Right Ladder Cable Tray for Your Project?

Choosing the right ladder cable tray for your project can be challenging. There are many options available. It is crucial to understand your requirements before making a decision. A ladder cable tray can efficiently manage cables. They provide support and protection, while ensuring proper airflow.

Consider your project's specifications. The size and weight of the cables matter significantly. If the tray cannot support the load, it will fail. Think about installation locations too. Different environments may affect the material selection. For instance, outdoor installations might need weather-resistant trays.

Reflect on future needs. Will your project expand? Will there be additional cables? Planning ahead can save time and money. Ultimately, the right ladder cable tray is not just about current needs. It's also about flexibility and longevity. Take the time to evaluate your options carefully.

Understanding Ladder Cable Tray Types and Applications

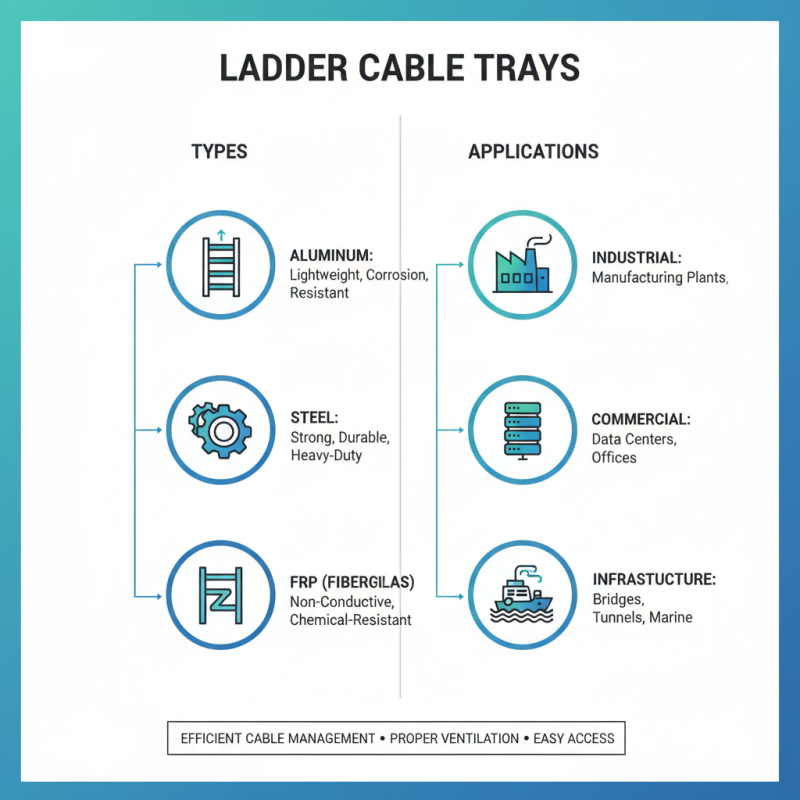

Choosing the right ladder cable tray is crucial for efficient cable management. Understanding the types and applications can prevent costly mistakes. Ladder cable trays are typically used for supporting and organizing cables in various environments. They allow for proper ventilation and easy access for maintenance.

There are several types of ladder cable trays available. Aluminum trays are lightweight and resistant to corrosion. Steel trays offer durability and strength. However, the choice often depends on environmental conditions and load requirements. A report from the National Electrical Contractors Association states that improper selection can lead to a 25% increase in installation costs.

Applications vary widely. Industrial settings often use heavy-duty trays, while commercial spaces might opt for lighter materials. It's important to consider factors like cable type and environmental exposure. Many projects overlook the impact of cable tray size, which can lead to overcrowding. Ensuring ample space can enhance performance and longevity. Addressing these details prevents issues down the line, ultimately saving time and resources.

Evaluating Load Capacity for Ladder Cable Tray Selection

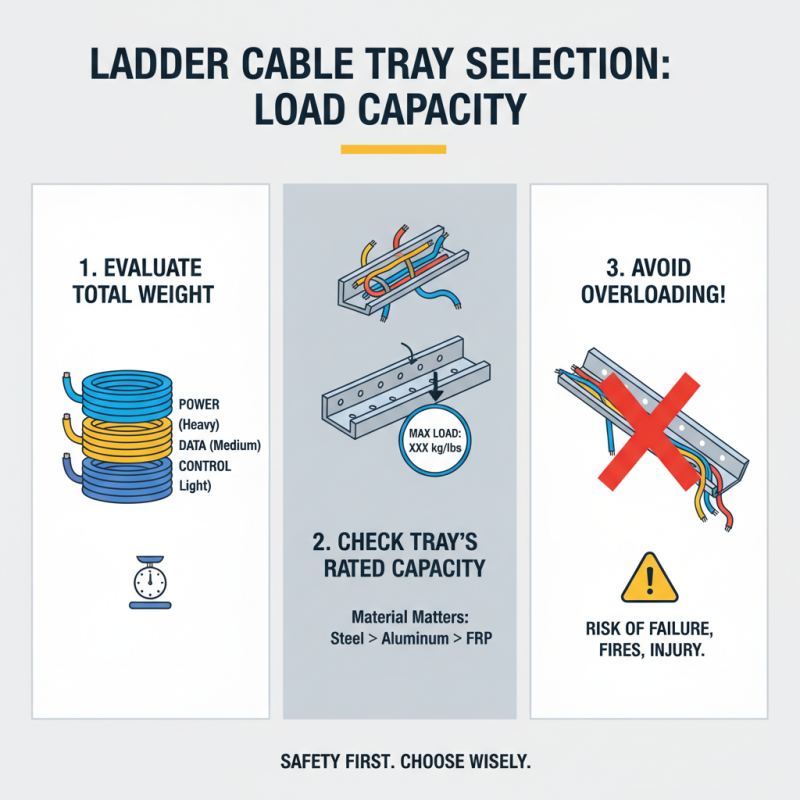

When selecting a ladder cable tray, evaluating the load capacity is crucial. A well-chosen tray supports all electrical cables efficiently. Overloading can lead to serious safety issues. It’s vital to understand the specific weights of your cables. Each material has a different weight, and this affects what the tray can hold.

Consider the cable's individual weight and the total length. Remember to account for future expansion. You might plan to add more cables later, which increases the load. If the expected load exceeds the tray's capacity, you risk bending or breaking the tray. Also, installation location impacts decisions. For example, a tray in a high-traffic area may need a higher load capacity due to potential impacts.

Not all installations are perfect. Sometimes, the tray can sag under unusual loads. This is a sign that the chosen capacity was not sufficient. Reflecting on past projects can provide insight. Did you underappreciate the weight of certain cables? Or overlook additional factors like environmental stresses? It’s these details that can make or break a successful setup.

Assessing Material Choices: Steel vs. Aluminum vs. Fiber-Reinforced Plastic

When selecting a ladder cable tray, material choice plays a crucial role. Steel, aluminum, and fiber-reinforced plastic (FRP) are common options. Each comes with specific benefits and drawbacks. Steel, for example, offers high strength and durability. However, it can be prone to corrosion, particularly in humid or salty environments. According to industry reports, nearly 30% of equipment failures are due to corrosion-related issues.

Aluminum is lightweight and resistant to corrosion. This makes it an excellent choice for outdoor applications. Its strength-to-weight ratio allows for easy handling and installation. However, aluminum may not hold up well under heavy loads. A report by the National Electrical Manufacturers Association states that aluminum can lose integrity under sustained stress if not properly supported.

Fiber-reinforced plastic, on the other hand, boasts excellent chemical resistance and is lightweight. It does not corrode, making it suitable for harsh environments. Yet, FRP can be more expensive than steel or aluminum and may require careful installation. The trade-offs in material choice highlight the need for project-specific evaluations. Each material has a unique lifecycle and performance profile that influences long-term costs and maintenance needs.

Material Comparison for Ladder Cable Trays

This bar chart compares the average costs of ladder cable tray materials: Steel, Aluminum, and Fiber-Reinforced Plastic. As shown, Steel tends to be the most expensive, while Fiber-Reinforced Plastic offers a more budget-friendly option.

Determining Installation Requirements and Compliance Standards

When selecting a ladder cable tray, understanding installation requirements is crucial. Begin by assessing the environment where the tray will be installed. Is it indoors or outdoors? Different settings have different needs. For example, outdoor trays must resist weather elements. This impacts material choice and installation methods.

Compliance standards play a significant role in the decision-making process. Local regulations often dictate installation practices. Ignoring these can lead to safety hazards. Make sure to check any industry-specific guidelines. Not adhering to compliance can cause project delays or costly modifications. It's important to consult professionals as they can offer valuable insights.

Installation can be tricky. Ensure all components fit perfectly; gaps can pose risks. Proper support is essential for the system's integrity. Consider the weight of the cables being used. A miscalculation here could lead to failure. Reflect on your planning process and be ready to adapt as needed. Mistakes can lead to greater challenges down the road.

How to Choose the Right Ladder Cable Tray for Your Project? - Determining Installation Requirements and Compliance Standards

| Cable Tray Type | Material | Load Capacity (lbs) | Width (in) | Height (in) | Installation Compliance Standards |

|---|---|---|---|---|---|

| Ladder Tray | Steel | 2000 | 24 | 3 | NEC, IEC |

| Ladder Tray | Aluminum | 1500 | 18 | 2.5 | NEMA, IEEE |

| Cable Tray | PVC | 800 | 12 | 2 | UL, CSA |

| Wire Basket Tray | Steel | 1200 | 30 | 4 | TIA/EIA, NEC |

Cost Analysis: Budgeting for Ladder Cable Tray Systems in Projects

Budgeting for ladder cable tray systems is crucial in any project. Costs can vary significantly based on factors like materials, size, and installation complexity. Typically, aluminum and steel options are available, each with its own price point. While aluminum is lightweight, it may not provide the durability that some projects need. Steel, on the other hand, offers robust support but can increase overall project costs.

It's also vital to account for installation expenses. Experienced labor may come at a premium. Failing to plan this can lead to unexpected overruns. Consider engaging multiple contractors for quotes. This allows for better comparison and budgeting accuracy. Remember, cheap labor can result in poor installation, costing more in the long run.

Consider maintenance costs as well. Ladder cable trays demand periodic inspections. Neglecting this can lead to serious issues down the line. Evaluate the total lifecycle cost, not just the initial purchase price. Sometimes, investing more upfront can save money over time. Reflecting on these details will lead to a more successful project. Planning effectively means avoiding costly mistakes later.

Related Posts

-

Top 10 Benefits of Using Cable Tray Wire for Efficient Wiring Solutions

-

Understanding the Importance of Cable Tray Wire in Modern Electrical Installations

-

Best B Line Cable Tray Solutions for Efficient Cable Management

-

Essential Tips for Installing Cable Tray Wire Efficiently and Safely

-

What is a B Line Cable Tray and How to Choose the Right One

-

Top 10 Benefits of Using Cable Tray for Your Electrical Wiring Needs

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now