Blog

How to Choose the Right Ladder Cable Tray for Your Project?

When it comes to selecting the ideal ladder cable tray for a project, clarity is key. David Thompson, a leading expert in cable management solutions, emphasizes, "Choosing the right cable tray can streamline installation and enhance cable performance." This insight underscores the importance of thoughtful selection.

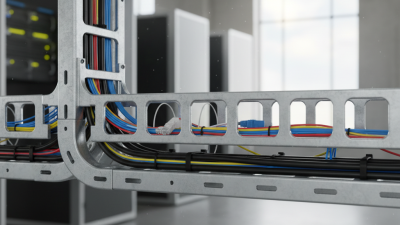

The ladder cable tray serves as a backbone for electrical systems. It provides support, ventilation, and ease of access for maintenance. Before choosing one, consider your project's specific needs. Is there adequate space for installation? What weight load must it support? These details matter immensely.

Yet, decisions are often not straightforward. You might find various sizes and materials on the market. Some trays look appealing but may not suit your installation's environment. Reflecting on these factors can help avoid missteps. Proper research today leads to a more efficient tomorrow with the right ladder cable tray.

Understanding Ladder Cable Tray Types and Their Applications

When selecting a ladder cable tray, understanding the different types is crucial. Ladder cable trays offer substantial support for various cable applications. They have a basic design, consisting of two side rails connected by rungs. This open design facilitates airflow, reducing heat buildup, which is often overlooked in project planning.

There are several variations of ladder trays. Some feature aluminum materials for lightness and corrosion resistance. Others might employ steel for added strength, but this can lead to increased weight. Consider the environment where the tray will be used. Indoor settings may require different materials than outdoor applications. The choice can significantly impact installation ease and durability.

Installation is another factor for consideration. An improperly installed tray can lead to cable damage or safety hazards. It is essential to think through every aspect of the project, including load capacity and future expansions. Upgrading to a heavier gauge can sometimes solve these issues, but it might not be necessary if the installation is done correctly. Reflecting on all these elements ensures a well-informed decision.

Types of Ladder Cable Trays and Their Applications

Factors to Consider When Selecting a Ladder Cable Tray

Choosing the right ladder cable tray can be a daunting task. There are several factors to consider. One important aspect is the material. Options like aluminum or steel each have pros and cons. Aluminum is lightweight but may not support heavy loads as well as steel. Think about your project's needs before making a decision.

The size of the cable tray matters too. Measure the cables you'll be using. Ensure the tray offers enough space for current and future needs. It's also wise to consider ventilation. A well-ventilated tray helps prevent overheating. This is particularly essential in environments with high temperatures.

Lastly, the installation process shouldn’t be overlooked. Some designs are easier to install than others. Reviewing installation requirements can save you time and frustration. A good choice may seem obvious, but it isn't always that simple. Reflect on your project demands carefully before deciding. Each project is unique and deserves particular attention.

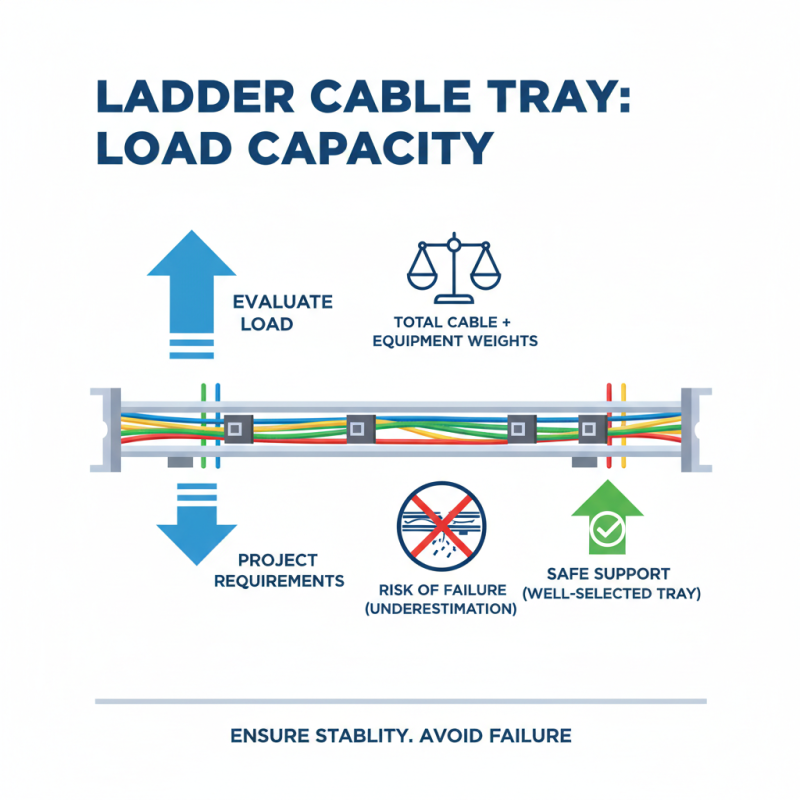

Evaluating Load Capacity and Environmental Conditions

When choosing a ladder cable tray, evaluating load capacity is crucial. Each project has specific weight requirements. Consider the total weight of the cables and any additional equipment. If you underestimate, it can lead to failure. A well-selected tray supports all necessary components without risk.

Environmental conditions play a significant role as well. Temperature, humidity, and exposure to chemicals matter. For instance, higher humidity might cause corrosion in some materials. Consider the location where the tray will be installed. Indoor areas may not face the same issues as outdoor settings. If not carefully chosen, the tray might degrade faster than expected.

It’s easy to overlook these factors during planning. Often, projects rush this part. Thinking about load and environment saves time and money later. Reflecting on past mistakes can improve future choices. Assess your project's unique needs thoroughly. This step will ensure a more reliable and safe installation.

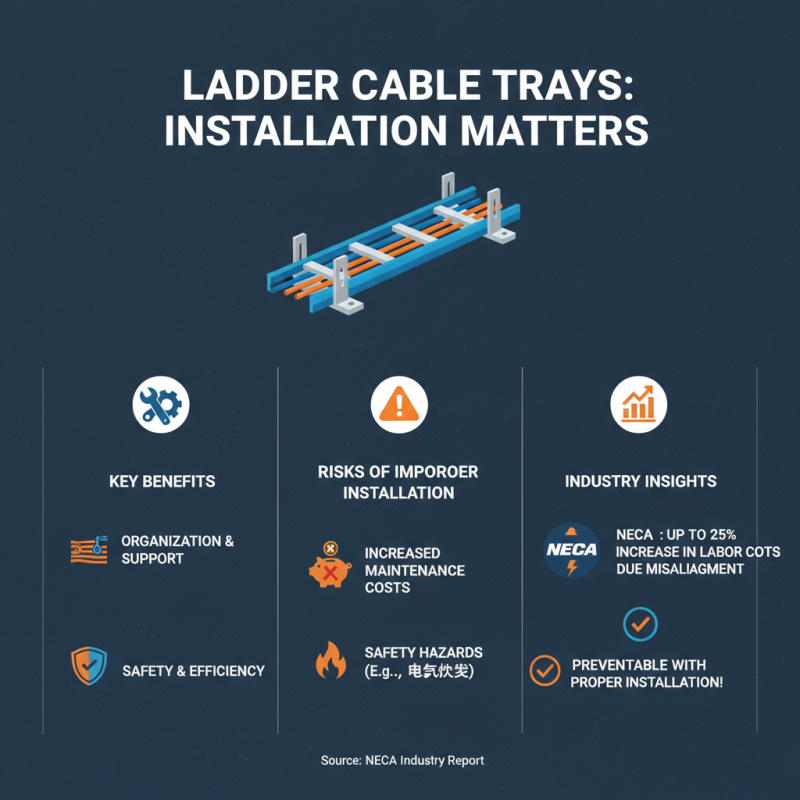

Installation Guidelines for Ladder Cable Trays

Ladder cable trays are essential for organizing and supporting electrical wiring. Proper installation is crucial for ensuring safety and efficiency. According to recent industry reports, improper tray installation can lead to increased maintenance costs and safety hazards. The National Electrical Contractors Association (NECA) estimates that misaligned trays can increase labor costs by up to 25%.

When installing ladder cable trays, precise measurements are vital. All supports must be leveled and spaced appropriately. The general industry standard suggests supports every 10 feet in straight runs. However, this number may differ based on the tray’s use and load. Each installation should closely follow local building codes, as deviations can lead to compliance issues.

Pay attention to the environment where the cable tray will be placed. Certain settings, such as chemical plants or outdoor sites, require specific materials. The tray must withstand the elements. Neglecting environmental factors can result in premature wear. Additionally, it's often easy to overlook proper grounding and bonding, which can lead to electromagnetic interference. This oversight can compromise system performance.

Maintenance Tips for Optimal Ladder Cable Tray Performance

Maintaining a ladder cable tray is crucial for its long-term performance. Regular inspections can help identify issues early. Check for debris accumulation, which can lead to blockages. Even a small amount can cause significant problems over time. Cleaning the tray regularly is essential. A simple wipe down can prevent corrosion and other damage.

Ensure that all connections are tight and secure. Loose fittings can lead to sagging or misalignment. It may seem minor, but it can affect the entire structure. Inspect the tray after heavy storms or maintenance activities. Such conditions may weaken the system unexpectedly. Look for any signs of wear, such as cracks or rust.

Documenting your maintenance procedures is wise. This record can help track when inspections occurred and what actions were taken. It serves as a reminder to stay proactive. Maintenance can become an afterthought if not routinely practiced. Schedule regular check-ups to avoid surprises. Remember, neglect can lead to costly repairs.

How to Choose the Right Ladder Cable Tray for Your Project? - Maintenance Tips for Optimal Ladder Cable Tray Performance

| Dimension | Description | Maintenance Tips |

|---|---|---|

| Material | Common materials include steel, aluminum, and fiberglass. | Inspect regularly for corrosion, especially in steel trays. |

| Load Capacity | Indicates the maximum load the tray can support. | Calculate load before installation, and do not exceed specifications. |

| Width | Available in various widths to accommodate different cable sizes. | Ensure proper spacing for airflow and maintenance access. |

| Height | Height varies based on installation area and cable volume. | Regularly check that cables are secured and not overloaded. |

| Length | Measured as per the route of installation based on project needs. | Inspect joints and connections periodically for stability. |

| Installation Environment | Indoor or outdoor applications can affect material choice. | Consider environmental factors like moisture and temperature fluctuations. |

Related Posts

-

Top 10 Benefits of Using Cable Tray Wire for Efficient Wiring Solutions

-

Understanding the Importance of Cable Tray Wire in Modern Electrical Installations

-

How to Choose the Right Ladder Cable Tray for Your Project?

-

Top 10 Best Electrical Cable Trays for Efficient Cable Management in 2023

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

The Future of Plastic Cable Tray Innovations and Sustainability

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now