Blog

Enhancing Electrical Safety: The Critical Role of Metal Cable Trays in Modern Infrastructure

In the ever-evolving landscape of modern infrastructure, electrical safety has emerged as a paramount concern, particularly with the increasing complexity of electrical systems. A critical component in achieving this goal is the implementation of metal cable trays, which provide essential pathways for the organization and protection of electrical wiring. According to industry reports, metal cable trays are known to reduce fire risks by up to 30% compared to traditional wiring methods, thanks to their superior durability and thermal conduction properties. Furthermore, the National Electric Code (NEC) emphasizes the importance of using non-combustible materials in electrical installations, further solidifying the role of metal cable trays in promoting safety. As industries strive to meet stringent safety standards and enhance operational efficiency, the significance of these robust structures will continue to grow, reflecting a broader commitment to safety in infrastructure development.

Understanding the Importance of Electrical Safety in Modern Infrastructure

Electrical safety is paramount in modern infrastructure, especially as our reliance on complex electrical systems continues to grow. According to a report by the National Fire Protection Association (NFPA), electrical failures are a leading cause of fires in commercial buildings, accounting for approximately 15% of all structure fires. This underscores the need for effective electrical management solutions, such as metal cable trays, which provide a safe and organized way to distribute electrical cables.

Electrical safety is paramount in modern infrastructure, especially as our reliance on complex electrical systems continues to grow. According to a report by the National Fire Protection Association (NFPA), electrical failures are a leading cause of fires in commercial buildings, accounting for approximately 15% of all structure fires. This underscores the need for effective electrical management solutions, such as metal cable trays, which provide a safe and organized way to distribute electrical cables.

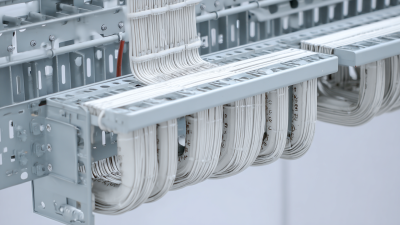

Metal cable trays play a crucial role in enhancing electrical safety by offering superior durability and protection against physical damage and environmental factors. In a study conducted by the International Electrotechnical Commission (IEC), it was found that installations utilizing metal cable trays experienced a 30% reduction in cable-related incidents compared to non-metal alternatives. These trays not only aid in maximizing airflow around electrical cables, reducing overheating risks, but also ensure compliance with industry safety standards, which is critical for preventing catastrophic failures. As infrastructure expands and evolves, prioritizing electrical safety through reliable solutions like metal cable trays is essential for safeguarding both people and property.

Choosing the Right Metal Cable Tray for Optimal Performance

When selecting the right metal cable tray for optimal performance, several key factors must be considered to ensure electrical safety and efficiency in modern infrastructure. Metal cable trays, often made from aluminum or steel, provide superior strength and durability compared to their non-metal counterparts. According to a report by MarketsandMarkets, the global cable tray market is projected to grow to USD 4.11 billion by 2025, demonstrating the increasing reliance on effective cable management solutions in various industries.

One critical aspect of choosing the right metal cable tray is understanding its load-bearing capacity. For instance, the National Electrical Manufacturers Association (NEMA) provides guidelines on the load ratings for different tray types, helping engineers select trays that can accommodate the specific weight and volume of electrical wiring while maintaining safety standards. Furthermore, factors such as the environmental conditions of the installation site—be it indoor or outdoor, exposure to corrosive substances, or varying temperatures—play a pivotal role in the material selection process. Selecting trays with appropriate finishes or coatings can further enhance their lifespan and performance.

Another consideration is the design and layout of the cable management system. A well-designed metal cable tray system not only organizes cables efficiently but also facilitates maintenance and reduces the risk of electrical hazards. Research by the International Electrotechnical Commission (IEC) highlights that properly installed and maintained cable trays can significantly reduce the likelihood of overheating and short circuits, thus contributing to a safer electrical environment. By paying close attention to these factors, professionals can ensure that the chosen metal cable tray will meet both current and future demands of their infrastructure projects.

Enhancing Electrical Safety: The Critical Role of Metal Cable Trays in Modern Infrastructure

| Cable Tray Type | Material | Max Load Capacity (lbs) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Ladder Tray | Steel | 2000 | Galvanized | Industrial Facilities |

| Perforated Tray | Aluminum | 1500 | Anodized | Commercial Buildings |

| Solid Bottom Tray | Stainless Steel | 3000 | Corrosion Resistant | Pharmaceuticals |

| Wire Mesh Tray | Steel | 1300 | Painted | Data Centers |

| Cable Ladder Tray | Aluminum | 1800 | Galvanized | Power Plants |

Installation Best Practices for Metal Cable Trays in Electrical Systems

When it comes to the safe and efficient management of electrical systems, the installation of metal cable trays holds critical importance. These trays not only support the weight and organization of cables but also play a pivotal role in enhancing electrical safety. According to the U.S. electrical conduit market report, the market size is projected to grow significantly, with an estimated worth of USD 1.72 billion by 2024, reflecting the increasing demand for reliable electrical infrastructure that promotes safety and efficiency.

Proper installation of metal cable trays is essential to comply with the National Electrical Code (NEC) requirements, particularly as they pertain to type TC cables. The NEC enables the use of TC cables for power and control circuits within cable trays, illustrating their versatility in complex installations. Moreover, installations should prioritize accessibility and maintainability to reduce the risks associated with untidy or improperly managed cables, a concern emphasized by the best practices in cable organization.

Incorporating effective cable management strategies not only adheres to safety standards but also improves overall project efficiency. Enhanced installation practices lead to minimal wear over time and ensure that electrical systems remain organized and functional, thereby mitigating hazards in both residential and commercial settings. As the industry evolves, understanding and implementing robust installation methods for metal cable trays will become increasingly vital.

Maintenance Tips for Enhancing the Longevity of Metal Cable Trays

Proper maintenance of metal cable trays is essential for ensuring their longevity and functionality in modern infrastructure. Regular inspections should be conducted to identify any signs of wear, corrosion, or damage. By checking for rust, loose fittings, and proper alignment, facilities can address potential issues before they escalate into costly repairs. It's advisable to clean the trays periodically to remove dust, debris, and moisture that could compromise their integrity.

Furthermore, applying a protective coating can significantly enhance the durability of metal cable trays. Using high-quality paint or specialized coatings designed for metal surfaces can prevent corrosion and extend the trays' lifespan. Additionally, ensuring that cable trays are correctly installed, with appropriate support and spacing, reduces stress on the materials, minimizing the likelihood of damage over time. Proper cable management within the trays, including avoiding overloading and using protective grommets for sharp edges, also contributes to safer and longer-lasting cable tray systems.

Compliance with Electrical Safety Standards: Key Considerations for Metal Cable Trays

Compliance with electrical safety standards is paramount in the installation and use of metal cable trays, particularly given their critical role in modern infrastructure. Metal cable trays, often constructed from galvanized steel or aluminum, help manage and protect electrical cables in commercial and industrial settings. According to the National Electrical Manufacturers Association (NEMA), proper installation and adherence to the National Electrical Code (NEC) guidelines are essential to prevent electrical hazards and ensure safe operations. NEMA emphasizes that using cable trays correctly can reduce the risk of overheating and electrical failures that lead to system downtime.

Furthermore, an analysis by the Occupational Safety and Health Administration (OSHA) highlights that nearly 20% of all workplace fatalities are caused by electrical incidents, making compliance with safety regulations vital. Key considerations when implementing metal cable trays include ensuring adequate load capacity, proper grounding, and appropriate spacing to prevent electromagnetic interference. Regular maintenance and inspections in line with the Canadian Standards Association (CSA) recommendations are crucial to ascertain that cable trays continue to function safely over time. By adhering to these standards and guidelines, organizations not only enhance their electrical safety protocols but also safeguard their investments in infrastructure.

Enhancing Electrical Safety: Metal Cable Trays Compliance Overview

Related Posts

-

Top Tips for Selecting the Best Cable Tray Wire Manufacturer for Your Needs

-

How to Choose the Right Black Cable Tray for Your Wiring Needs

-

The Future of Plastic Cable Tray Innovations and Sustainability

-

How to Select the Right Basket Cable Tray for Your Wiring Needs

-

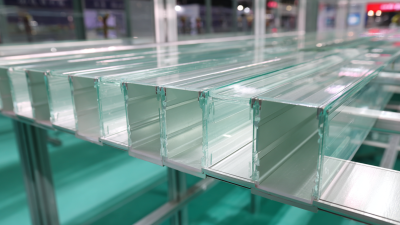

Exploring the Future of Fiberglass Cable Trays at the 138th China Import and Export Fair 2025

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now