Blog

Maximizing Safety and Efficiency: The Growing Demand for Basket Cable Trays in Modern Infrastructure

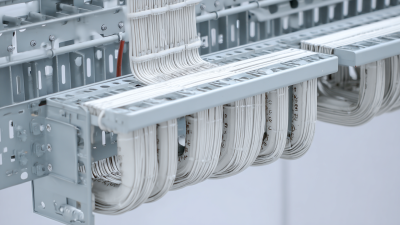

In the rapidly evolving landscape of modern infrastructure, the demand for efficient and safe cable management solutions has surged, with basket cable trays emerging as a vital component. According to a recent report from the Research and Markets, the global cable tray market is expected to reach USD 6.92 billion by 2026, growing at a CAGR of 5.1% from 2021. This growth is largely driven by the increasing need for organized cabling systems in commercial and industrial environments, where safety and efficiency are paramount. Basket cable trays, known for their lightweight design and ease of installation, are becoming the preferred choice among engineers and project managers. Their ability to support high-volume cable loads while maintaining optimal airflow is essential, especially in facilities requiring stringent adherence to safety standards. As infrastructures become more complex, leveraging the benefits of basket cable trays will not only streamline installation processes but also enhance overall operational safety, making them indispensable in contemporary construction projects.

Understanding the Basics of Basket Cable Trays and Their Applications

Basket cable trays are an essential component in modern infrastructure, specifically designed to support and manage electrical and data cabling. These trays, typically made of steel or lightweight aluminum, offer an effective solution for both commercial and industrial applications. According to a report by Research and Markets, the global cable tray market is projected to reach approximately $4.5 billion by 2027, with basket cable trays experiencing significant growth due to their efficiency and safety in cable management.

One of the key advantages of basket cable trays is their ventilation capability, which prevents overheating and improves the longevity of the cables contained within. This is particularly crucial in environments where heat dissipation is paramount, such as data centers and industrial facilities. The flexibility in installation also plays a significant role; basket trays can adapt to various conditions and configurations, making them ideal for retrofitting existing structures. The National Electrical Manufacturers Association (NEMA) specifies that the use of cable trays can reduce installation time by up to 30%, indicating a clear preference for integrating these systems in modern builds.

Moreover, basket cable trays contribute to a cleaner work environment by minimizing clutter and promoting easy access for maintenance. The growing emphasis on safety regulations in infrastructure projects further enhances the demand for these trays, as they reduce the risk of fire hazards associated with tangled wiring. As companies seek to maximize both efficiency and safety in their operations, the adoption of basket cable trays will likely continue to rise across various sectors.

Evaluating Safety Standards and Compliance in Cable Tray Installation

In the evolving landscape of modern infrastructure, the demand for basket cable trays is increasingly linked to the rigorous safety standards and compliance measures that govern installation practices. According to a recent report from the National Fire Protection Association (NFPA), improper installation of cable trays is a leading cause of fire hazards in commercial buildings, which highlights the critical nature of adhering to established safety guidelines. Basket cable trays, with their open design that promotes better airflow and reduces heat accumulation, not only support the efficient management of electrical wiring but also align with safety protocols defined in standards like the National Electrical Code (NEC).

Furthermore, industry analysis reveals that over 40% of electrical engineers prioritize compliance with safety standards during the selection of installation materials. This growing emphasis on safety and efficiency is evident in the increased investment in training programs focused on cable tray installation, ensuring that professionals are well-versed in the prevailing regulations. With materials like galvanized steel and aluminum being favored for their durability and resistance to corrosion, the installation of basket cable trays is seen as a proactive measure to mitigate risks and enhance the reliability of infrastructure, paving the way for safer and more efficient operational environments.

Maximizing Safety and Efficiency: The Growing Demand for Basket Cable Trays in Modern Infrastructure

| Installation Location | Material Type | Load Capacity (lbs) | Compliance Standard | Safety Rating |

|---|---|---|---|---|

| Commercial Buildings | Steel | 2000 | UL 2024 | A+ Rating |

| Industrial Facilities | Aluminum | 1500 | CSA C22.2 | A Rating |

| Healthcare Facilities | Galvanized Steel | 1800 | ANSI/TIA-606 | A+ Rating |

| Data Centers | Stainless Steel | 2500 | NEC 300.22 | A Rating |

| Educational Institutions | Composite Material | 1200 | ISO 9001 | A Rating |

Optimizing Cable Management: Best Practices for Basket Tray Systems

Basket tray systems have become essential in modern infrastructure due to their ability to optimize cable management effectively. These systems are designed to support a variety of cables while ensuring that airflow is not obstructed, which helps in maintaining the integrity and performance of electrical systems.

One of the best practices for implementing basket cable trays is to conduct a thorough site assessment before installation. This includes understanding the specific needs of the project, identifying potential hazards, and determining the best layout for cable runs to maximize accessibility and safety.

Another critical practice is to ensure proper installation and maintenance of the basket trays. Utilizing high-quality materials that comply with industry standards can significantly enhance the durability and safety of the installation. Furthermore, regular inspections and maintenance schedules should be established to identify any wear or issues that may arise over time. By adhering to these best practices, organizations can create an efficient cable management system that mitigates risks and ensures long-term functionality in their infrastructure.

Enhancing Efficiency with Proper Planning and Design of Cable Trays

The design and planning of cable trays are crucial for enhancing efficiency in modern infrastructure. With the increasing complexity of electrical systems, effective cable management solutions like basket cable trays have gained prominence. These trays not only provide significant organization but also facilitate easier access for maintenance and upgrades. Proper planning ensures that these installations accommodate future expansions and changes in technology, reducing the need for costly modifications down the line.

Incorporating basket cable trays into the initial design phase allows for streamlined wiring processes and improved airflow, which are essential for preventing overheating. Additionally, strategic placement of these trays can minimize the risk of cable damage and electrical hazards, thereby enhancing overall safety. By considering factors such as load capacity, material choice, and environmental conditions during the planning stage, infrastructure projects can achieve greater reliability and efficiency, meeting the demands of modern electrical systems while keeping safety as a top priority.

Increasing Longevity: Maintenance Tips for Basket Cable Trays Systems

Basket cable trays have become increasingly popular in modern infrastructure due to their ability to accommodate large volumes of cables while ensuring safety and efficiency. However, to extend the lifespan of these systems and maintain their effectiveness, regular maintenance is crucial. According to a report from the National Electrical Manufacturers Association (NEMA), inadequately maintained cable tray systems can lead to an 18% increase in operational costs, highlighting the importance of preventive care in reducing potential issues.

To maximize the longevity of basket cable tray systems, facilities should implement a scheduled inspection routine that focuses on identifying signs of wear, corrosion, and cable overcrowding. The Cable Tray Institute recommends inspecting the trays at least bi-annually, ensuring that any accumulated dust or debris is removed to prevent airflow obstructions and overheating. Moreover, proper installation techniques must be adhered to, as incorrect setups can lead to cable strain and eventual failure. By following these best practices and relying on industry data, organizations can enhance the performance and durability of their basket cable tray systems significantly.

Related Posts

-

What are the Benefits of Using B Line Cable Tray in Electrical Installations

-

Ultimate Guide: How to Select the Right Flexible Cable Tray for Your Industrial Needs

-

5 Best Cable Tray Wire Solutions for Efficient Wiring Management

-

Understanding the Challenges of Wire Cable Tray Systems: Insights and Solutions from Industry Experts

-

Exploring Innovative Alternatives to Traditional Cable Tray Wire Systems

-

How to Choose the Right Black Cable Tray for Your Wiring Needs

Exclusive Access

Unlimited Resources

Detailed information on our products to assist you with the planning of your cable management project

Register Now